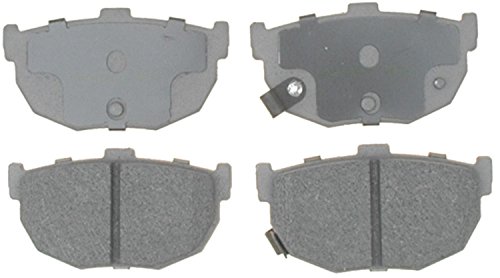

ACDelco

14D323A

ACDelco 14D323A Advantage Organic Rear Disc Brake Pad Set with Wear Sensor

EAN: 0707773758281

UPC: 707773758281

SKU: ADW14D323A

Brake Pads

Features and Benefits

ACDelco Advantage Friction brake pads feature the fit, form and function of premium aftermarket brakes at a more economical price. The ACDelco Advantage line offers dependability, performance and great value — without sacrificing important features and benefits. Chamfered, slotted and shimmed to provide similar fit, form and function of the OE service part. Hardware clip kits included (where applicable). Have multiple formulations including both ceramic and semi-metallic pads that are specific to the vehicle application. Product backing plate is painted Grey to easily differentiate from ACDelco DuraStop or ACDelco OE Service parts. Tested to SAE 2430\SAE2784 to help assure quality. 12-month/12,000-mile warranty*

* Whichever comes first. To the original retail purchaser. Parts only; installation not included. See your local retailer or independent service center that offers ACDelco parts for details.

Function & Signs of Wear

Find out more about ACDelco Advantage Friction parts and how they fit into the Brakes System with the product facts below.

Brake Pads:

FUNCTION: Flat pads with frictional materials contact the rotor to help slow or stop the vehicle (disc brakes).

SIGNS OF WEAR: Chirping, grinding or squealing noise, difficulty stopping the vehicle.

Brake Shoes:

FUNCTION: Shoes press against the inside of the brake drum to cause friction in order to slow or stop the vehicle (disc brakes).

SIGNS OF WEAR: Insufficient friction material on brake shoes, reduced braking ability, low brake pedal height, longer stopping distances, squealing or unusual noises, brake pedal pulsation.

Did You Know?

When you step on your brake pedal, you command a stopping force 10 times as powerful as the force that puts the car in motion. The brakes system can exert as much as 1,000 pounds (450 kg) of hydraulic pressure on each of the four brakes.

What It Does

The Brake System applies frictional force to the wheels to slow or stop the vehicle.

Service & Maintenance

The following inspections and maintenance procedures can help prevent potential brake problems:

Check brake fluid level at every oil change. Replace fluid according to Owner's Manual recommendations.

Calipers and wheel cylinders should be checked every brake inspection and serviced or replaced as required.

Inspect the brake lines for rust, punctures or visible leaks (you may be able to do this, but consult a qualified technician if necessary)

The following should be conducted by a qualified technician:

- Inspection of the brake hoses for brittleness or cracking

- Inspection of brake lining and pads for wear or contamination by brake fluid or grease

- Inspection of wheel bearings and grease seals

- Parking brake adjustments (as needed)

Used rotors can be machined provided minimum thickness can be maintained:

Before you machine rotors, make sure the lathe is clean, within specs and has sharp tool bits.

After completing the finish cut, sand both sides of the rotor for one minute per side using a sanding block and 130- to 150-grit sandpaper to obtain a non-directional finish.

After sanding, wash the rotor with dish soap and water. DO NOT clean the rotor with brake cleaner/solvent-based product.

Thoroughly clean the calipers, caliper slides and hardware. Remove all dirt, rust and grease.

Great brake pad performance at a great value.

Lucas Electrical Fuel Temp. Sensor

Total Source SWITCH STOP 84340 76004 71 84340-76004-71

Mix me 1630